How we designed the circular Mono Air Houdi

Every detail matters

Here we share all the secrets behind our latest innovation: The Mono Air Houdi. The goal is to enable co-creation and a circular transformation of the apparel industry, not to spawn cheap copies of Mono Air Houdi. Get creative, remake, rethink, go fully circular and think holistically. Then you will be our friend forever!

Main fabric: Polartec® Power Air™ Lightweight

The main fabric is essential for the concept of the Mono Air Houdi. The fabric is called Power Air™ Lightweight and is produced by Polartec® in Cleveland, Tennessee. It’s a high performance light fleece fabric constructed to prevent the shedding of microfibers without compromising on functionality. It is made from recycled and recyclable polyester, ensuring a circular lifecycle. A top tier technical fleece fabric that is both circular and anti-shedding is nothing short of groundbreaking.

Supplier: Polartec Art nr: 1709

Beside the sustainability benefits, Polartec® Power Air™ Lightweight has all the performance qualities that we could wish for. The fabric is light (288 g/m²), stretchy, and highly durable. It has a great balance between breathability and wind resistance. All in all, it is just what you need for a 4-season insulation garment for skiing, climbing, hiking or any other outdoor adventure.

Read everything about the fabric technology and get in touch with Polartec here.

Mono Air recipe

The technology for using recycled polyester for several of these components exist. It is a question of demand before suppliers start making them. With a collaborative effort, where more brands start demanding recycled versions instead of virgin ones and mono material versions replace mixed, we could transform even the smallest components from linear to circular.

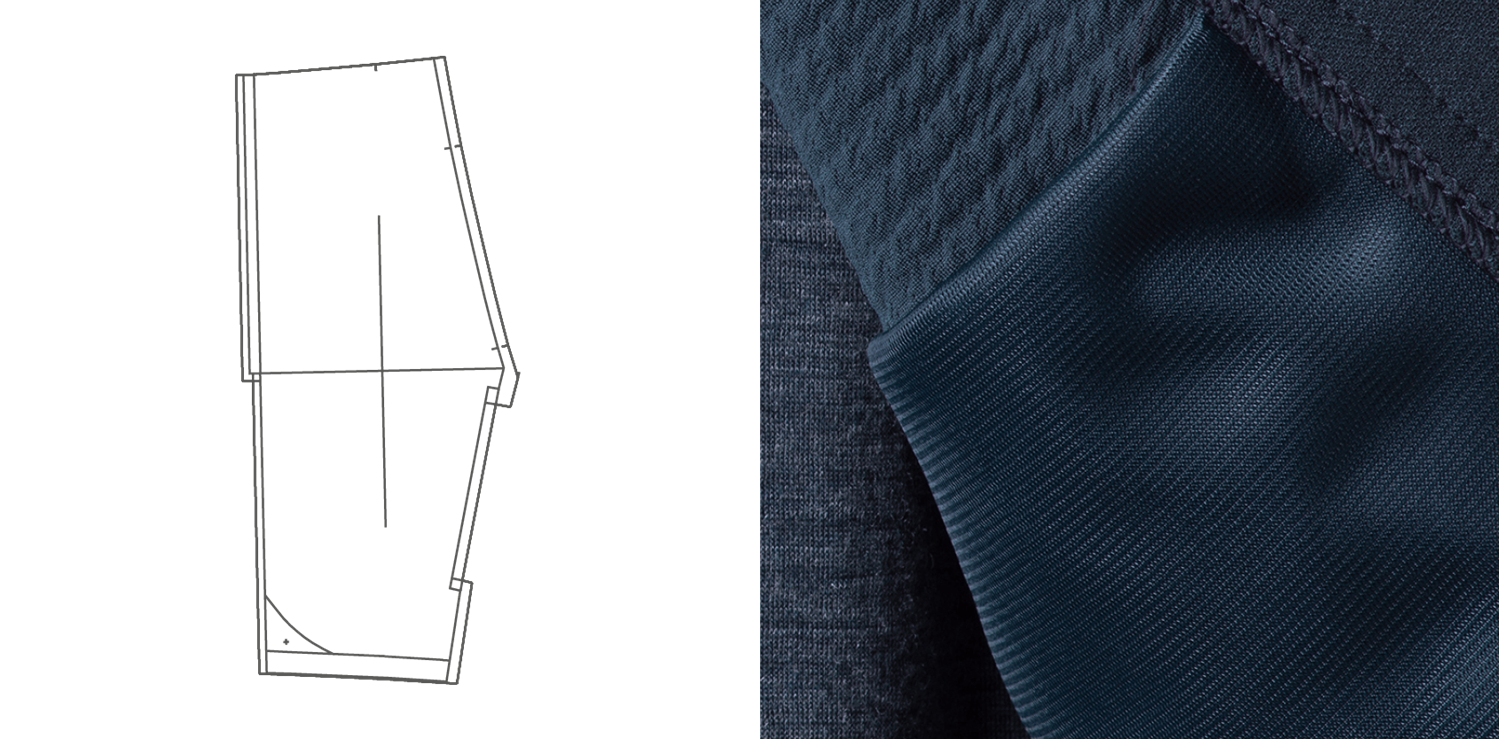

Cut and fit

In Mono Air Houdi, we are looking for the ultimate balance between performance and comfort. The stretch in the fabric allows us to create a rather snug fit that fits nicely underneath a shell jacket without feeling too tight. The shoulder has a raglan sleeve that gives the shoulders room to move. To give that cozy feeling of comfort, we have designed a high, snug collar and added the thumb loops at the end of the sleeves. The neck and the wrists are the main contact points between the garment and your skin. They are also sensitive pulse points on the body. The thumb loops eliminate drafts around the wrists. The hood fits perfectly underneath the hood of a shell layer and the snug fit lets it move with your head to never get in the way. The garment has a slight back drop to create extra comfort. We believe that those small things that create a feeling of comfort is highly important when you are out in the wild exposed to nature's elements. The cut is also optimized to minimize production waste. Cutting a garment from a piece of fabric is like cutting cookies from a dough and the cutting should be adjusted to minimize waste.

One step closer to a waste free world

Colors

The fabric is dyed using only Bluesign® certified dyestuff. Bluesign® is a third party organization monitoring to make sure no substances are used that can cause harm to people or nature. All the water that is used is cycled back into the production.

Colors is more than just production. It is science, performance, mood and caracter. With inspiration from nature we develop a wide variation of timeless tints and shades. Colors with integrity, that exist above and beyond seasonal trends, age with beauty.

Packaging

Mono Air Houdi is shipped from the factory in a standard, thin plastic sleeve. The main purpose of the sleeve is to protect the garment during shipping and handling in the warehouse. It might seem a bit counter-intuitive to use a plastic wrapper on a garment designed to fight plastic waste and we are in the process of finding a better alternative, but at this point, this is our best option. Plastic does have some undeniable advantages, it’s very light (which means less energy for shipping), it’s durable and protects that garment from both dirt and moisture. It can be made from recycled plastics and also be recycled again in a circular system, which is the route we have chosen.

IF the plastic is recycled, which is the case in some countries including here in Sweden, it has a very low environmental impact. But even though we know many of our customers around the world care as deeply as we do about recycling, we can never guarantee that these bags don’t go astray. All in all, the plastic bag does the job very well, but is not optimal in the linear world of today. We are working on alternatives and recognize several initiatives for eliminating single use plastics as well as developing circular solutions. One such is the European Outdoor Group’s Single Use Plastics Project.

https://www.europeanoutdoorgroup.com/singleuse/singleuseplastics-en

Meet the Mono Air family

Light and durable hooded fleece jacket for men. Features an innovative fabric construction that prevent microfiber shedding and is made with recycled and recyclable fibers.

$ 230.00

$ 138.00

Light and durable hooded fleece jacket for women. Features an innovative fabric construction that prevent microfiber shedding and is made with recycled and recyclable fibers.

$ 230.00

$ 138.00

Light and strong multifunctional women’s fleece jacket with a high collar and half-zip. The innovative fabric construction prevents microfiber shedding and the material is recycled and recyclable.

$ 220.00

$ 110.00

Houdini Sportswear. All rights reserved.